Why does the air filter air volume become smaller? Shared by metal Filter Discs supplier.

Why is the air volume of air filter smaller? I believe that many customers have some doubts about this problem in the process of product use. Today we will explain several reasons why the air volume of air filter decreases.

First, confirm whether the final resistance of the air filter (that is, its reported value) has reached the final resistance during the use of the product. Generally, the final resistance value of the air filter is 400-600pa.

Two: whether the front end primary filter and the middle filter of the air filter have also reached the final resistance value. Because of the former primary effect, the middle effect mainly plays the role of protecting the air filter. If the front end primary effect and the middle effect filter has reached the reported destruction value, it will also affect the air volume of the air filter.

Three: air conditioning unit problem is not the air volume of the air conditioning unit in the use of the process has reached the whole purification space to the air volume.

Above is the air filter related content, hope to be helpful to you.

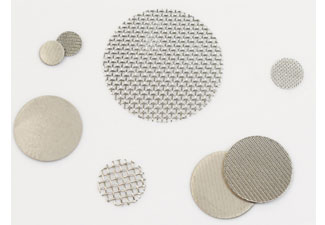

Wire Cloth Filter Discs

How to clean stainless steel screen effect?

As everybody knows, stainless steel filter in use after a period of time, on the surface of the screen will appear a lot of filtering impurities, if it is not clear in time, will affect the filtration precision and the quality of the product is unqualified, so regular cleaning stainless steel filter is very important, but we have to grasp the method.

Stainless steel filter screen plays a very important role in the filter equipment, regular cleaning for the service life of the filter screen and the purity of the filter products have played a very important role, especially in some chemical industry, sewage treatment system, high-precision products need to be cleaned often to get qualified products.

Surface of the product itself is made by metal wire woven, filtration precision is relatively concentrated, if you must need to pay attention to when cleaning the surface of the scratch, if destroyed structure, is equivalent to directly damage the filter of a complete set of products, also need to pay attention to the stainless steel filter can not always clean, the service life of the product are not.

So, the regular cleaning of stainless steel filter mesh is very important, I hope that through the above introduction of everyone can have more understanding of the cleaning of stainless steel filter mesh and matters needing attention, for the service life of the product and the precision of the filter have the corresponding help.

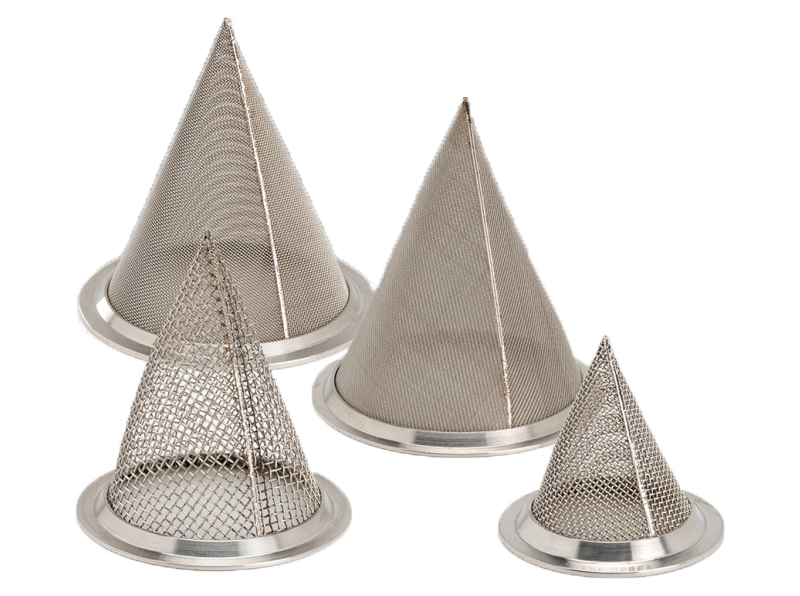

We supply Wire Mesh Cone Strainer Filter, welcome to purchase our products.