1, hook mesh [inclined square net, diamond mesh] hook, the characteristics of weaving simple, beautiful and practical, the material has high quality low carbon steel wire, stainless steel, aluminum alloy wire, purposes: for the security of the court, green fence, river, construction, residential protection.Specification: 1/2 inch 1 2 inches, wire diameter: 2.2-4.06 mm.

2, ginning network (pre-bending forming network) weaving features: rolling before weaving, structure: single wave isolation bending, double wave isolation bending, locking bending, flat bending, bidirectional bending.Features: fixed structure, long service life, materials: black iron wire, white steel wire, lead wire, stainless steel wire.USES: mainly used in mining, coal yard and construction industry.Specification number of mesh: 1-21 mesh threads from o.5-4.8mm.

3, steel mesh, woven, characteristics: hardness, tensile force, wear - resistant and firm.The material is made of no. 45 steel wire rod drawn into no. 23 wire [0.61 mm] or above, used in mining, metallurgy, construction, medicine and other industries.Specification: 6-38 mesh, wire diameter: 0.61-0.132.

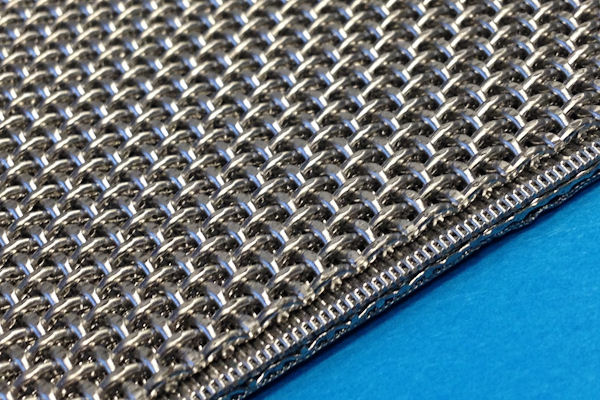

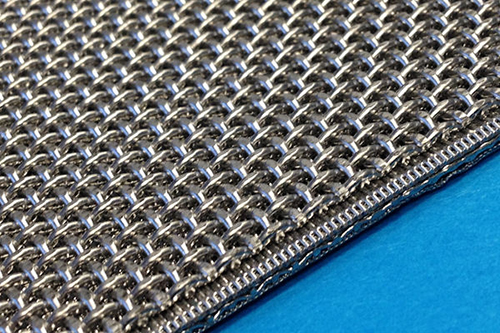

4, the conveyor belt network, its organizational structure shape has ordinary weaving, reinforcement weaving, segmented ordinary weaving.Materials: stainless steel wire, stainless steel wire, medium and low carbon steel wire, galvanized wire, nickel chrome wire, ferrochrome aluminum wire, polyester wire, application: used in petroleum, metallurgy, food processing, machinery, pharmaceutical, glass, printed circuit board equipment and other industries.

5, mining screen, weaving and point, rolling, welding, the material is stainless steel wire, used for coal mines, mines and other industries, the kind of seam screen, screen blue, garden screen.

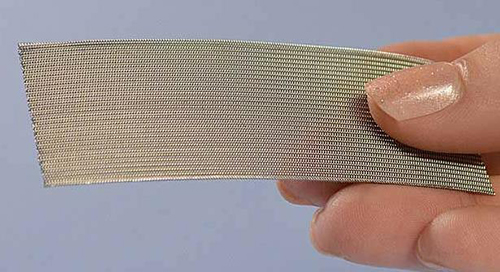

6, oil vibrating screen mesh, stainless steel wire woven, characteristics of the acid and alkali resistance, high temperature resistance, abrasion resistance, used in oil shale shaker, specifications: mesh number 7-10.36-211 mesh, mesh 0.075 mm 2 mm, wire diameter 0.045 0.45 mm, with single hook vibrating screen cloth, double hook vibrating screen cloth, single layer, double vibrating screen cloth adhesive vibrating screen cloth.

7,

Air bleed screen filter mesh, with wire hook weaving and become, the characteristics of good Air permeability, material has stainless steel wire, copper wire, galvanized iron wire, nylon yarn, use used in petroleum, chemical industry, metallurgy, machinery, pharmaceutical, ethylene synthetic ammonia industry, such as chemical fiber, automobile, environmental protection through steam pavilion absorbing evaporating filtering to remove of fog, foam, gas and liquid, and various kinds of particles in the Air.

8. Industrial filter cloth [non-woven fabric] is woven with silk thread, and the wire is woven with polyester, polyamide, vinylon and nylon silk thread, which is characterized by temperature resistance, acid resistance and alkali resistance. It is used in food, chemical industry, dye, ceramics, metallurgy, pharmacy, etc.The types are: polyester staple plain filter cloth, thickness 0.4-1.6 mm, strong acid resistance, weak alkali resistance;Polyester short twill press cloth, thickness 0.45-0.7 mm, strong acid resistance, alkali resistance;Polyester long fiber high strength press cloth, thickness 0.22-o. 62 mm, acid and slightly alkali resistant;Nylon strong silk filter cloth, thickness 0. I8-0.54mm, strong acid resistance, slightly alkali resistance: polypropylene long polyester high strength filter cloth, thickness 0.30o-0.5mm, strong acid resistance, strong alkali resistance: vinylon uniform fabric, thickness 0.45mm, strong acid resistance, weak base resistance: polyester polyester dust cloth, thickness 0.63-0.80mm, strong acid resistance, weak base resistance.

9, thorn rope, the earlier the spine cord is composed of twist plait, galvanized barbed wire, barbed wire, PVC now new products for the blade thorn rope, made from high strength steel wire core, made from a mix of galvanized sheet and stainless steel plate blade of block equipment, this network model is not easy to touch and can achieve excellent protective isolation effect, characteristics have a deterrent effect is good, beautiful, construction is convenient, economical and practical advantages.It is mainly used for the protection of garden, apartment, office, prison, post and so on.The types are linear blade gill net, spiral blade gill net, spiral cross blade gill net and blade protection net.

10, guardrail network, steel wire weaving, welding, the types are: 1, protective network, highway, iron road, airport, port, municipal construction, breeding, etc.;

2. Decoration net, parks, lawns, hotels, recreation grounds, wholesale markets, supermarket shelves, handicrafts, etc.

3. Construction network, used for building buildings and roads;

Its characteristic is firm and durable, do not rust, beautiful and easy, anticorrosive form has electroplating, heat plating, spray plastic, dip plastic and so on.

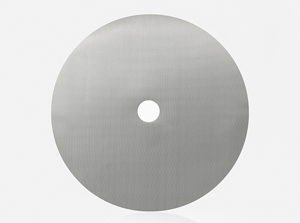

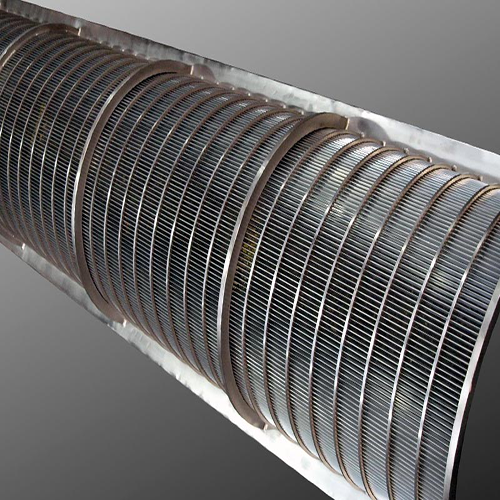

Stainless Steel Metal Filter Tube

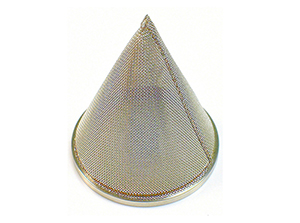

11, filters, paint is made of high quality

stainless steel metal filter tube developed filter, filter, filter, and other industrial use melt filter, material with metal mesh, metal fiber, metal powder, chemical fiber, filter, filter cloth, etc.The structure forms are sheet, tubular, tubular, cup-shaped, folding, winding, line gap, candle type, frame, basket, box type, plate type and so on. Widely used in power, petroleum, chemical, metallurgy, machinery, textile, medicine, automobile, air conditioning and other industries screening and filtering.