Brief introduction of Sintered Mesh performance:

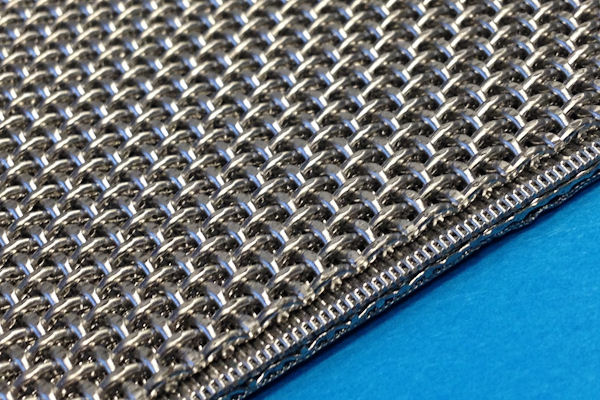

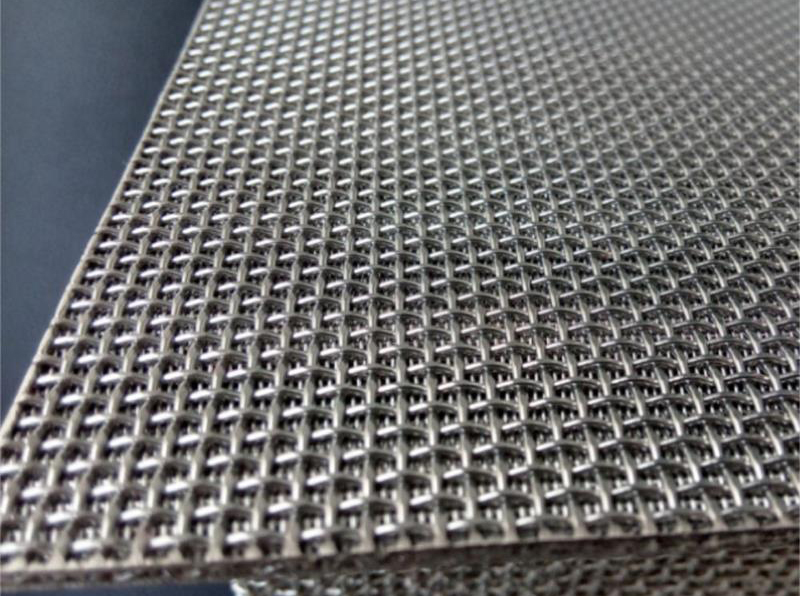

The Sintered Mesh Laminate is a new type of material whose main component is stainless steel sintered mesh. It has good filtering effect and uniform surface filtration performance. The pore of sintered mesh is crossed, not only resistant to high temperature, but also resistant to quenching and heat, it can be used in corrosive environments, and suitable for various acid and corrosive media.

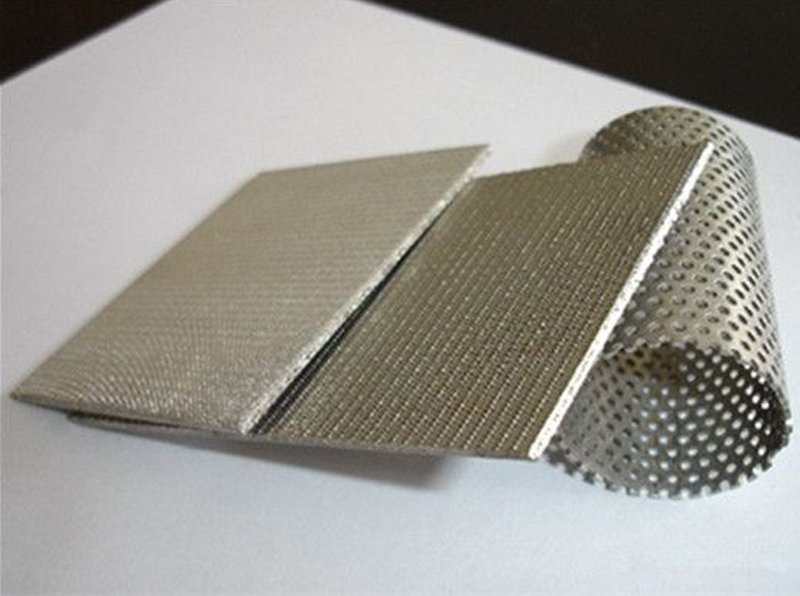

Metal Sintered Wire Mesh has high strength and wear resistance, suitable for filtration of sulfur-containing gas especially. Its toughness is good, and can be welded in high pressure environment. Sintered wire mesh has stable filtration performance and good reproducibility, even if after repeated cleaning, the filtration performance can be restored to more than 90%. in addition, the structure is stable and not deformed easily. There has Five Layer Sintered Mesh, single layer sintered mesh, perforated metal sintered wire mesh, their size can be adjusted according to needs, and can be used in high and low temperature environments.

Which industries will sintered mesh be used in the society?

Sintered Mesh is a commonly used filter material, it is made of micron-sized metal fiber by superposition and high temperature sintering, and has good filtration precision larger dirt holding capacity. So it has been widely used in various industries in the society.

Sintered Wire mesh can be used for recovery of catalysts, filtration of hydraulic system, semiconductor industry filtration and so on. Most hydraulic system for civil aircraft use the sintered mesh, and various high density processors and memory chips use a filter of sintered mesh to purify, and the result is more efficient and more convenient to use.