We are a custom metal screen supplier.Since 1998, we have noted the need for mesh filters and have set our goal as a leading manufacturer of mesh filter products.

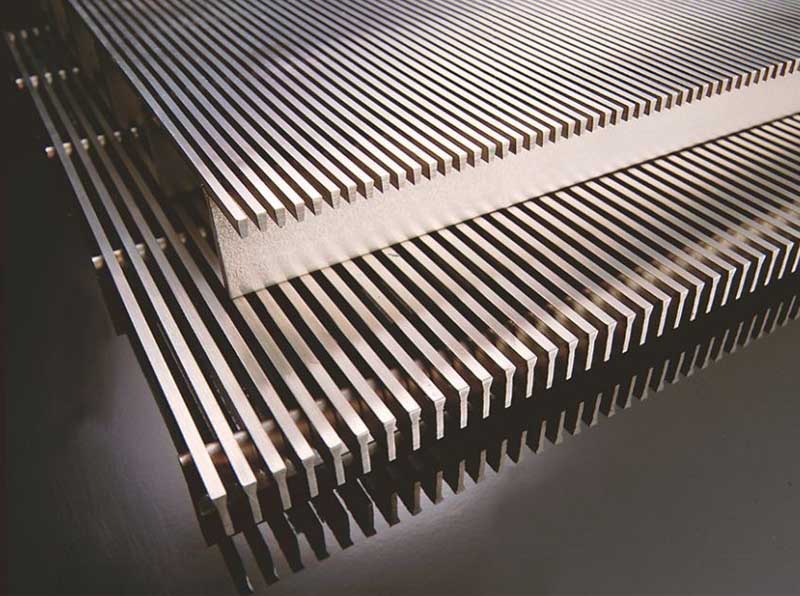

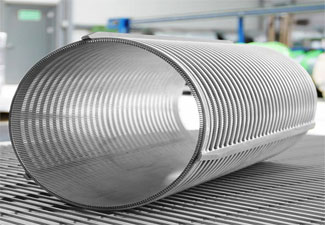

Wire screen is a combination of metal and wire mesh. Wire mainly refers to the wire made of metal and non-metal materials. Wire mesh is a kind of wire woven into different shapes, densities and specifications according to the needs.

Main uses:

Silk screen is a traditional industrial product in China, which has a wide range of applications in scientific research, production and life. With the rapid development of science and technology, at present, the application of wire mesh, petroleum, chemical industry, automobile, papermaking, food, construction, aviation, aerospace and other industries and high-tech fields.

Classification:

Stainless steel mesh, steel plate mesh, mat type mesh, copper wire mesh, hexagonal mesh, electric welding mesh, window screen, square hole mesh, sunscreen, conveyor belt mesh, protective screen, ginned mesh, crochet mesh, screen plate mesh, nickel mesh, rope mesh, mineral mesh, polyester mesh, plastic flat mesh, steel wire mesh, sintered felt, barbecue mesh, paper mesh, printing mesh, thorn rope, drug mesh, nylon mesh, electric welding mesh, black silk cloth , sound net, gabion net, chemical etching net, blade barbed rope, battery net, earphone net, industrial filter cloth, metal filter net, vibration screen, gas-liquid filter net, air conditioning net, construction safety net, American grid net, breeding net, etc.

Stainless Steel Wire Mesh Baskets

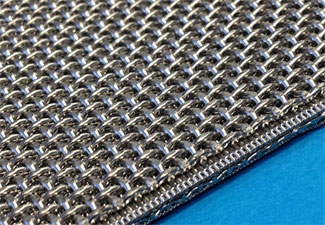

Introduction of stainless steel wire mesh weaving mode and its characteristics:

1. Plain weave:

Each diameter thread crosses each weft thread up and down

The weaving mode in which each weft thread crosses the top and bottom of each diameter thread.

2. Twill weaving:

Each diameter thread crosses each 2 weft threads

The weaving mode in which each weft thread crosses each two diameter threads

3. Dense plain weave:

Each diameter thread crosses one weft thread

A weave in which each weft is crossed up and down a diameter

Add up value of latitudinal wire diameter a25.4mm ≤ a28mm

4. Dense twill weave:

Each diameter thread crosses each 2 weft threads

The weaving mode in which each weft thread crosses each two diameter threads

Add up value of weft wire diameter a50.8mm ≤ a ≤ 56mm

5. Three braids:

Each diameter thread crosses each and every two weft threads. At the same time, each weft thread crosses each and every two diameter threads

The way of weaving through the bottom

6. Five braids:

Each diameter thread crosses each and every 4 weft threads

The weaving mode in which each weft thread crosses each and every four diameter threads, or each diameter thread crosses each two and every three weft threads up and down, and each weft thread crosses each two and every three diameter threads up and down.