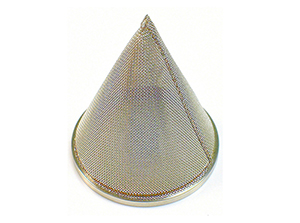

Inspection method of customized stainless steel cone strainer:

Inspection of knitting accuracy. It is divided into 3 levels: first-level accuracy, the limit deviation of the mesh cannot exceed 6%; second-level accuracy does not exceed 9%; third-level accuracy does not exceed 12%; mainly the inspection of the arithmetic mean of mesh Inspection of large mesh size.

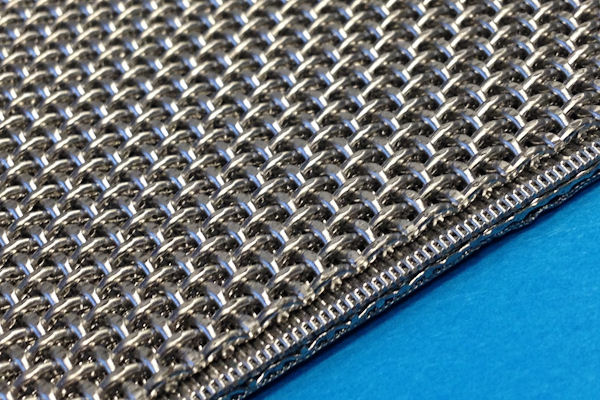

Inspection of the quality of weaving. It is impossible for metal wire mesh to be free of manufacturing defects during the production process. Generally, metal meshes delivered in rolls are not allowed to have major defects, a small number of important defects are allowed, and a certain number of general defects are allowed.

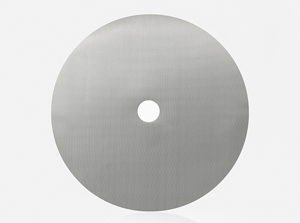

Stainless Steel Mesh Filter Disc

The following conditions of the stainless steel filter on the weaving process are major defects: the warp and weft are not firmly intertwined, and the two warp and weft threads are rubbed up and down, and the warp and weft threads have obvious loose displacement. The natural curl diameter is less than 80mm; the mesh is less than 0.18mm, and the natural bend diameter of a 1m long mesh is less than 60mm, which should be judged as unqualified.

The main function of air bleed screen filter mesh:

Due to the long-term industrial pollution, which has caused the decline in air quality, we all know that no matter what the circumstances, the untreated air, etc., contains a lot of harmful substances. Production has a great impact, and it is also harmful to our bodies.The quality of the products produced will also be substandard.

Air filters can greatly help production, improve the quality of compressed air and reduce the cost of production. Air filters are generally made of stainless steel, which are selected according to different filter materials and designs. Filter elements come out, so that we can meet our requirements for water quality.

The air filter is a fast device that can be selected, so that it is more convenient and simple to exchange the filter element, and it is more convenient for us to clean it.This kind of equipment is used in many industries, and it is also the best equipment for each type that requires filtering treatment. The anti-corrosion of the air filter is very strong.

How to clean the sintered mesh filter cartridge:

Sintered mesh filter cartridge plays a very important role in filtering equipment. Regular cleaning plays a very important role in the service life of the filter and the purity of the filter product, especially in some chemical industries. In sewage treatment systems, high-precision products require frequent cleaning to obtain qualified products.

The surface of the product is woven from metal wire, and the filtration accuracy is relatively concentrated. If you must pay attention to surface scratches during cleaning, if the structure is damaged, it is equivalent to directly damaging the entire set of filter products.In addition, stainless steel filtration that needs attention The net is not always cleanable, and the products have a certain service life.